All about copper leaching: chemical leaching, bio-heap leaching, and sustainability

June 24, 2025

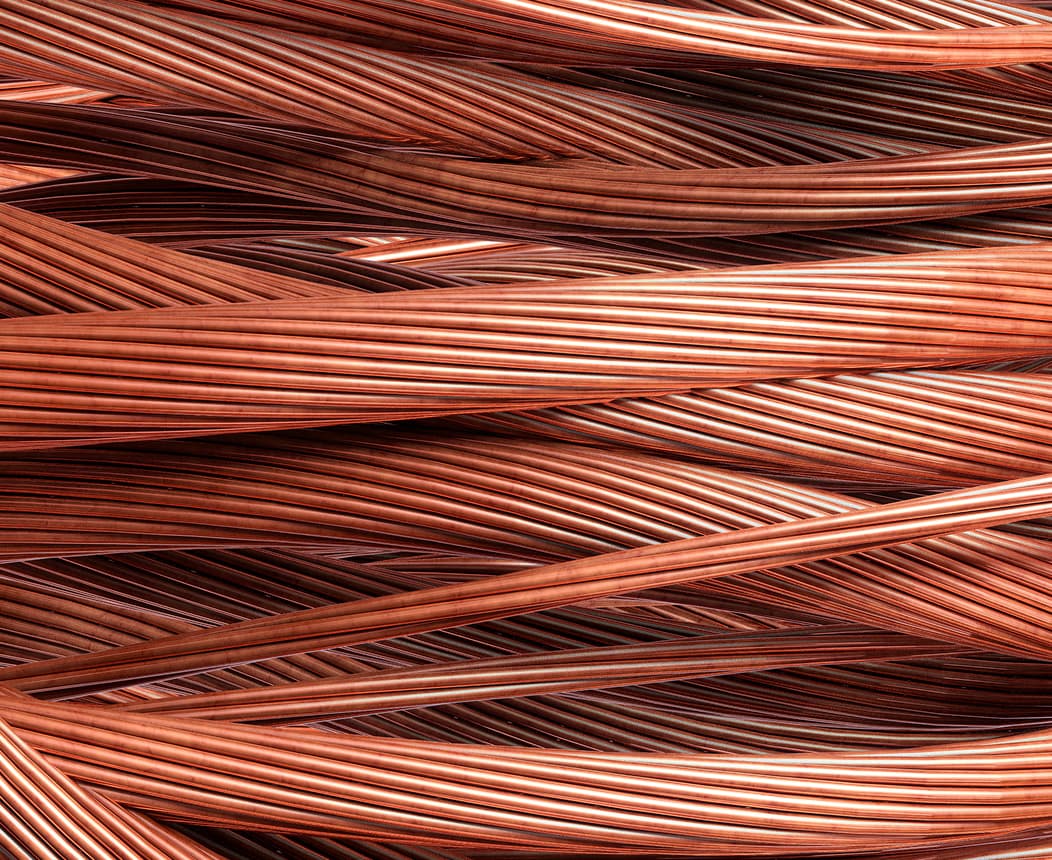

Copper is everywhere: in the wires that power our homes, the electronics we use daily, and the infrastructure that keeps the world moving. But how do we extract this essential metal in a way that makes sense for both the economy and the environment? Enter heap leaching, a smarter, cleaner, more efficient method of copper extraction that works hand in hand with traditional mining to maximize recovery while minimizing environmental impact. Nuton’s bio-heap leaching technology takes this process even further, using the power of bacteria to extract more copper with less chemicals and less impact on the earth.

Chemical heap leaching: process and downsides

Chemical heap leaching has been around since the 1700s, and has since been widely adopted alongside—or in place of—traditional mining techniques. By trickling a sulfuric acid solution over heaps of crushed ore, miners can extract more copper at lower costs. This method is surface-based and uses impermeable liners to prevent contamination, making it an efficient choice for many operations.

But while chemical heap leaching is effective, it comes with trade-offs. The process relies on strong chemical solutions that must be carefully managed to prevent environmental damage. Plus, producing and handling these chemicals requires energy, adding to the overall footprint of the process. It’s a step in the right direction, but there’s a better way.

Bio-heap leaching: a superior and sustainable solution

What if we could harness nature to do the heavy lifting? That’s exactly what Nuton’s bio-heap leaching technology does. Instead of relying on harsh chemicals, it uses microorganisms—tiny but mighty—to break down copper minerals more efficiently. This not only reduces the risk of contamination but also cuts down on energy use, making it a cleaner, smarter approach.

And the benefits don’t stop there. Bio-heap leaching can recover up to 85% of copper from ores, which means more copper from the same volume of material. This process helps in reducing waste and making operations more cost-effective. It’s also incredibly versatile, working on challenging sites, including brownfield and legacy mining areas, where traditional methods struggle.

“Bio-heap leaching can recover up to 85% of copper from ores, which means more copper from the same volume of material. This process helps in reducing waste and making operations more cost-effective.”

Paving the way in sustainable copper leaching

As the world’s demand for copper grows, so does the need for more sustainable ways to extract it. Nuton’s bio-heap leaching technology leads the charge, turning mining into a cleaner, more efficient process. While chemical heap leaching offers advantages, bio-heap leaching enhances them by improving recovery rates and slashing environmental impact.

Innovative leaching methods like these are paving the way for a future where mining and sustainability go hand in hand. And that’s good news for everyone.